SEARCH

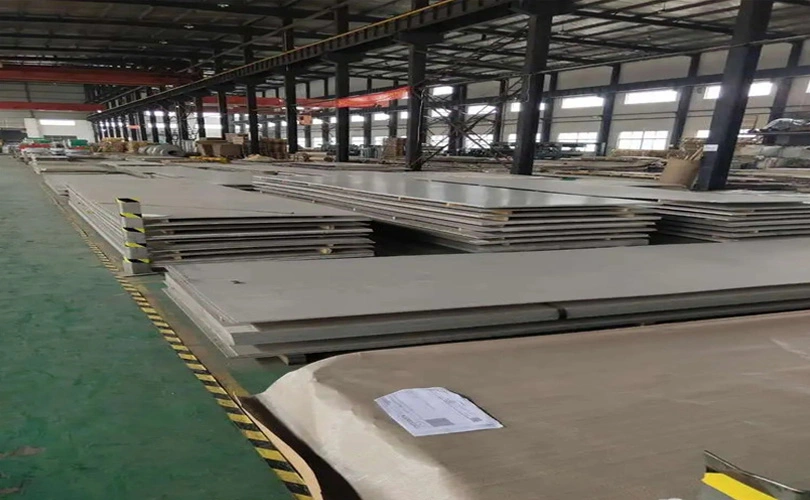

Aulisiter is one of the leading high-quality special metal manufacturers, including titanium, tantalum, niobium, zirconium, nickel, tungsten, molybdenum, hafnium, cobalt, and vanadium. Our special metal range encompasses rods, tubes, plates, flanges, and custom-made components. These nonferrous metals, known for their strength and durability, cater to a wide array of industries such as aerospace, medical, and construction. As a professional nonferrous metals company, we are committed to delivering top-quality products and ensuring customer satisfaction has solidified Aulisiter's position as a trusted name in the special metal materials market.

Titanium, tantalum, niobium, zirconium, nickel, vanadium, cobalt, molybdenum, tungsten, and gold are all renowned for their durability. These nonferrous metals are resistant to corrosion and wear, making them ideal for use in harsh environments or in applications where longevity is crucial. They can withstand high temperatures and pressures, further enhancing their durability.

These special metals are incredibly versatile, with a wide range of applications across various industries. For instance, custom titanium products are used in aerospace for its strength and lightness, while gold is used in electronics due to its excellent conductivity. Tantalum products and niobium products are used in capacitors, and nickel products and cobalt are used in batteries. This versatility makes these types of non ferrous metals invaluable in modern technology.

These non ferrous magnetic metals including sputtering target material offer high performance characteristics that are unmatched by other materials. For example, tungsten has the highest melting point of all metals, making it ideal for high-temperature applications. Molybdenum is known for its high thermal conductivity and low thermal expansion, making it useful in electronics and industrial applications. Vanadium and zirconium metal for sale are used in nuclear reactors due to their neutron-absorbing properties.

Heat treatment: Titanium tube for sale needs to be heat treated during the manufacturing process to improve their hardness and strength. The heat treatment process usually includes three steps: heating, holding and cooling.

Cold processing: The titanium tube after heat treatment needs to be cold processed to further improve its hardness and strength. The cold working process usually includes steps such as cold rolling, cold drawing and cold pressing.

Welding: The welding of titanium pipes requires special technology, because the special metal titanium is easy to react with oxygen, nitrogen, hydrogen and other non ferrous metal types at high temperatures to form brittle compounds, affecting the quality of the weld. Therefore, the welding of titanium tubes usually needs to be carried out under inert gas protection.

Surface treatment: The surface treatment of titanium tubes usually includes pickling, grinding, polishing and other steps to improve its surface quality and corrosion resistance.

PHONE

ADDRESS

Gaoya Village Industrial Park, Banyu Town, Baoji City, Shaanxi Province, China