SEARCH

As a leading titanium wire factory with 14 years of rare metal research and development experience, Baoji Aulister company has always been committed to providing high-quality titanium wire products to customers around the world. Titanium wire has become an indispensable core material in modern industry due to its excellent strength-to-weight ratio, corrosion resistance and biocompatibility. This article will deeply analyze the uses of titanium wire and explain the importance of choosing a professional titanium wire company.

Titanium wire is highly valued in the aerospace industry. Its excellent strength-to-weight ratio makes it an ideal material for aircraft manufacturing. According to a study by the International Institute for Aerospace Materials, "Titanium alloys, including those used in wire form, are used in critical aerospace components such as aircraft landing gear and engine parts. Titanium's low density helps reduce the overall weight of the aircraft while maintaining high strength and corrosion resistance." With 14 years of experience in the production of exotic metal materials, including titanium, our company is fully capable of providing high-quality titanium wire for aerospace applications. As a leading titanium wire factory, we ensure that our products meet the most stringent aerospace standards.

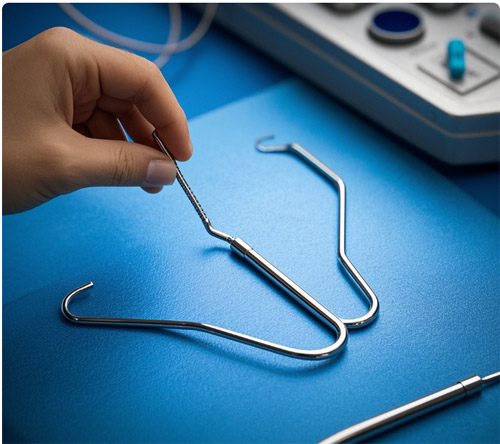

The medical field has also found numerous uses for titanium wire. Titanium is biocompatible, which means it can be safely implanted in the human body. It is used in orthopedic implants, such as screws and plates, to aid in bone repair. In dental applications, titanium wire is used in braces to straighten teeth. A research paper published in the Journal of Biomedical Materials Research states: "The biocompatibility and mechanical properties of titanium wire make it a material of choice for medical devices that need to be implanted for a long time." As a professional titanium wire manufacturer, our company is committed to producing medical grade titanium wire that meets the highest quality and safety standards.

Titanium wire is also widely used in industrial environments. It is used in the production of chemical equipment because it can withstand harsh chemical environments. In the automotive industry, titanium wire is used in high-performance engines to reduce weight and improve efficiency. A report from the Industrial Materials Association states: "The corrosion resistance and high-temperature stability of titanium wire make it an important material in industrial applications." As a long-established titanium wire factory, our company is able to customize titanium wire according to the specific requirements of different industrial applications.

The application of titanium wire has penetrated into daily life. Its delicate metallic luster and anti-allergic properties make it a preferred material for high-end jewelry and smart watch straps. Apple's patent disclosed in 2023 shows that titanium wire is used to enhance the structural strength of the Apple Watch Ultra case.

In the field of microelectronics, ultra-fine titanium wire with a diameter of 0.1mm can be used as a flexible circuit board connection line or as a current collector in lithium batteries.

From life-saving medical implants to spacecraft that explore the universe, the boundaries of titanium wire applications are still expanding. As a titanium wire factory with 14 years of experience in the industry, Baoji Aulister company will continue to drive development with innovation and provide global partners with better quality and more professional titanium material solutions.