SEARCH

Our specialty materials, in the form of rods, wires, sheets, tubes, and forgings, are tailored to withstand the harshest of power plant environments. Their exceptional properties, such as high corrosion resistance and exceptional tensile strength, ensure uninterrupted energy production, even under extreme conditions.

By investing in Aulister's specialty materials for your power generation needs, such as zirconium alloys in nuclear applications, you can rest assured of dependable performance, durability, and longevity – key factors in sustainable energy production.

Titanium's Pivotal Role in Power Plants:

Aulister's titanium components, known for their exceptional strength, corrosion resistance, and high-temperature stability, play a pivotal role in power plants. From turbine blades to heat exchangers, our materials contribute to the efficiency and reliability of energy generation systems.

Nickel's Efficiency in Electrical Components:

Nickel, recognized for its conductivity and durability, is a cornerstone in electrical components used in power generation. Aulister's nickel materials ensure the longevity and performance of critical components, such as generators and transformers.

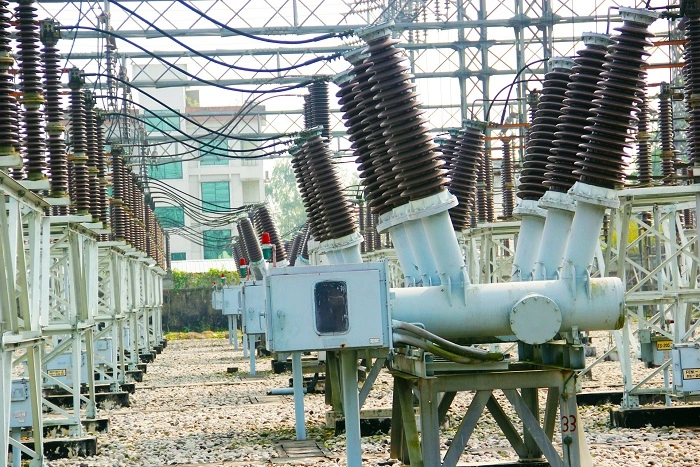

Tungsten's Endurance in Energy Transmission:

Tungsten's density and hardness make it an ideal choice for components in energy transmission systems. Aulister's tungsten products, including wires and plates, contribute to the durability and efficiency of high-voltage equipment, ensuring a reliable power grid.

Molybdenum's Heat Resistance in Nuclear Power:

In the realm of nuclear power, molybdenum's high melting point and heat resistance are indispensable. Aulister's molybdenum products, including rods and sheets, are vital components in nuclear reactors, ensuring the safety and stability of energy production.