SEARCH

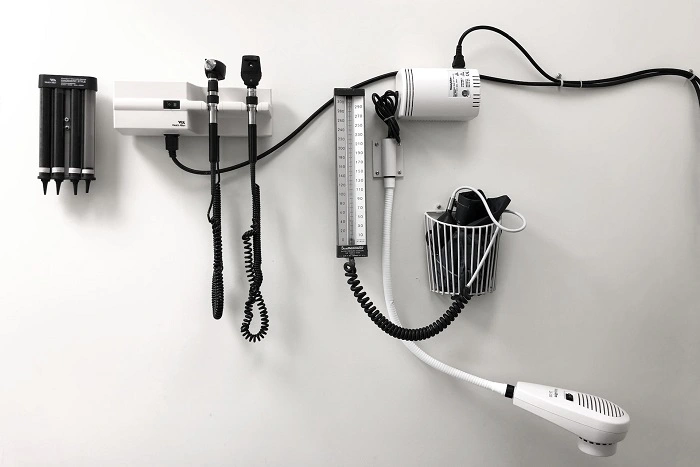

Our titanium, niobium, zirconium, and other exotic metals are used in a variety of medical applications, from surgical tools and implants to diagnostic equipment. These materials offer unique properties such as biocompatibility, corrosion resistance, and strength, making them ideal for use in medical devices. At Aulister, we pride ourselves on our commitment to research and development, ensuring that our materials meet the evolving needs of the medical industry. Let us help you create the next generation of medical devices that improve patient outcomes and enhance overall healthcare.

Revolutionizing Medical Devices with Titanium:

Aulister's titanium components, celebrated for their biocompatibility and corrosion resistance, are instrumental in the creation of cutting-edge medical devices. From surgical implants to diagnostic equipment, our titanium materials ensure durability and compatibility with the human body.

Nickel's Precision in Medical Imaging:

In the realm of medical imaging, precision is paramount. Aulister's nickel materials, with their exceptional magnetic properties, contribute to the development of MRI components, ensuring high-quality imaging for accurate diagnoses.

Tantalum's Role in Life-Saving Implants:

Life-saving medical implants demand materials of the highest caliber. Aulister's tantalum products, known for their resistance to corrosion and bioinert properties, are pivotal in the creation of cardiac stents and other critical implants.

Molybdenum's Surgical Precision:

Molybdenum, prized for its high melting point and strength, is a cornerstone in surgical instruments. Aulister's molybdenum products, including wires and sheets, contribute to the precision and reliability of surgical tools used in delicate procedures.