SEARCH

The most commonly used titanium alloy, known for its high strength, light weight, and excellent corrosion resistance. It's often used in aerospace applications.

Products | Size(mm) | Condition | Grade Nos | Specification |

Titanium & Titanium Alloy Rods & Bars | Φ(30~400)×L≤5000 | Forged bars | Gr1, Gr2, Gr5, Gr12 | ASTM, ASME, AMS, MIL, JIS, ISO |

φ(8~60)×L≤4000 | Rolled bars |

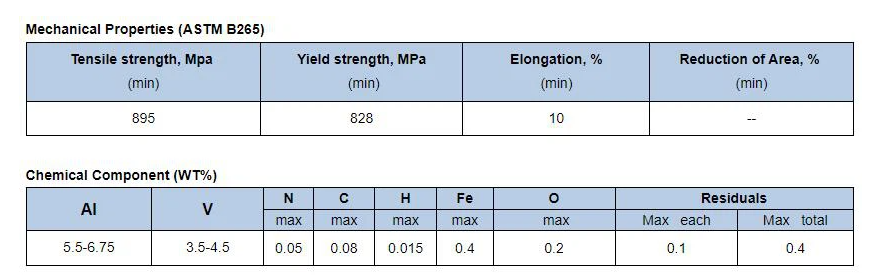

Commonly referred to as Ti-6AL-4V (or Ti 6-4), this designation refers to its chemical composition of almost 90% titanium, 6% aluminum, 4% vanadium, 0.25% (max) iron and 0.2% (max) oxygen. It features excellent strength, low modulus of elasticity, high corrosion resistance, good weldability, and it is heat treatable. The addition of aluminum and vanadium increases the hardness of the material in the alloy matrix, improving its physical and mechanical properties.

Grade 5 Ti-6Al-4V Titanium Bar is a kind of titanium alloy product, including 6% aluminum and 4% vanadium, is a kind of titanium alloy, which is frequently used with moderate intensity, it can be used in the welding structure, the highest temperature can reach 600°F and covering 50% of the world total amount of titanium.

Ti-6AL4V titanium round bar stock is also aging hardenable by heat treatment to achieve even higher strengths. This biocompatible material is also well suited for medical implants. Its mechanical and physical properties allow good capacity for titanium to join with bones and other tissue

Ti 6AL4V Titanium bar stock can be machined using slow speeds, high feed rates, ridged tooling, and flooding the workpiece with non-chlorinated cutting fluid.

Standards: ASTM B348, ASME SB348, AMS 4928, AMS4930, AMS 4965, AMS 4967

Product Shapes: round bar ,square bar, hex bar, rectangular bar

Application Fields:

• Manufacturing

• Construction industry

• Medical industry

• Marine navigation

• Aircraft aviation

• Chemical engineering

• Sports equipment

PHONE

ADDRESS

Gaoya Village Industrial Park, Banyu Town, Baoji City, Shaanxi Province, China