SEARCH

Elevate Performance with Custom Titanium Wire Engineered for Excellence

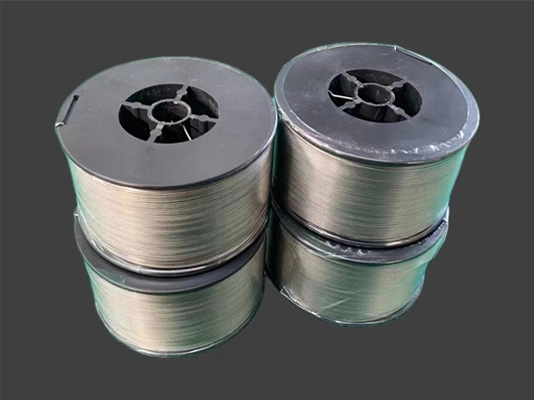

Titanium wires are high-performance, lightweight metal conductors made from titanium and its alloys. These custom titanium wires boast an exceptional combination of strength, corrosion resistance, and biocompatibility, making them indispensable in aerospace engineering for critical components and medical applications like orthopedic implants, dental devices, and surgical instruments. The low density and superior fatigue resistance of custom titanium wires also allow for use in springs, precision machinery, and electronics where durability and reliability are paramount. With excellent formability and weldability, custom titanium wires can be tailored to meet specific industry needs across a variety of sectors. Sourced from a reputable titanium wire factory, these products ensure consistent quality and performance.

Custom titanium wires play a significant role in construction and infrastructure due to their unique properties. The high strength-to-weight ratio and exceptional corrosion resistance of custom titanium wires make them ideal for tensioning cables in bridges, architectural structures, and seismic retrofitting systems. Sourced from a reputable titanium wire factory, these custom titanium wires ensure reliability and performance in critical applications.

In reinforcing concrete and composite materials, these custom titanium products provide lightweight yet durable reinforcement. The ability to procure titanium wire wholesale allows construction projects to maintain cost-effectiveness. Furthermore, the biocompatibility of custom titanium wires enables their use in environmentally friendly green building applications, such as soil stabilization and erosion control meshes. The wires' ability to withstand harsh environments extends their application in coastal and marine projects.

By integrating custom titanium wires into various construction and infrastructure projects, engineers can achieve durable and reliable solutions. Titanium wire wholesale options provide access to high-quality materials from titanium wire factories, enhancing the performance and sustainability of construction applications. The unique properties of custom titanium wires make them indispensable for innovative infrastructure solutions. Gain a competitive advantage with our custom titanium wires!

PHONE

ADDRESS

Gaoya Village Industrial Park, Banyu Town, Baoji City, Shaanxi Province, China