SEARCH

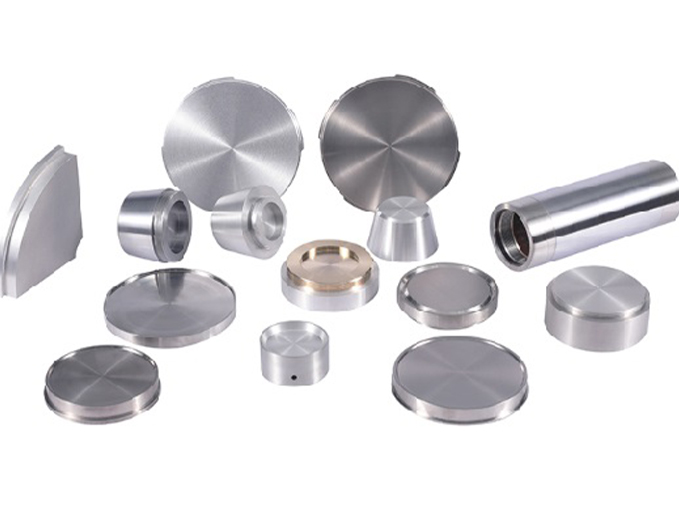

Sputtering target materials are critical components in the process of sputtering, a widely used technique in the physical vapor deposition (PVD) of thin films. This custom sputtering targets process is essential in the fabrication of semiconductor devices, solar panels, optical components, and many other applications where thin layers of sputtering target material need to be deposited with high precision and uniformity.

1. High-Quality Film Deposition

Among non ferrous metal types, sputtering target material allows for the deposition of films with high purity and uniformity. The quality of the film is directly related to the purity and composition of the sputtering target material, enabling precise control over the film’s properties.

2. Wide Range of Materials

Almost any custom sputtering targets material including zirconium sputter target, titanium sputtering target, tial target and chromium target can be sputtered, including metals, alloys, ceramics, and composites. This versatility allows for a broad range of thin films to be produced, catering to diverse applications from semiconductor devices to protective coatings.

3. Excellent Adhesion

Films deposited by sputtering typically exhibit excellent adhesion to the substrate. This is due to the energetic particles in the sputtering process, which can create a stronger bond between the film and the substrate.

PHONE

ADDRESS

Gaoya Village Industrial Park, Banyu Town, Baoji City, Shaanxi Province, China